AlpineSIP at Māja I 2025 – The International Construction Exhibition in Riga!

We are excited to announce that AlpineSIP will be participating in Māja I 2025, the leading international construction exhibition in Riga! This event is a great opportunity to showcase our innovative building solutions, including SIP panels and POSI-JOIST beams.

Visit our stand to explore how our high-performance materials can help you build stronger, more energy-efficient, and sustainable structures. Our team will be there to answer your questions and demonstrate why AlpineSIP is the right choice for modern construction.

We look forward to connecting with industry professionals, builders, and homeowners looking for smarter construction solutions.

See you at Māja I 2025 in Riga! 🇱🇻

#AlpineSIP #Māja2025 #InternationalConstructionExhibition #SIPPanels #PosiJoist #SustainableBuilding #ConstructionInnovation

POSI-JOIST Solutions for Floors and Flat Roofs

We are excited to announce that we have expanded our production capabilities by acquiring the latest-generation Mitek Posi-Joist truss manufacturing equipment. Starting in January 2025, we will offer our clients innovative and reliable solutions for floors and flat roofs using Posi-Joist technology.

What is Posi-Joist?

Posi-Joist is a modern truss system that combines the best properties of wood and metal elements. The main advantage of this technology is the ability to create lightweight yet strong structures, providing greater flexibility and efficiency in construction projects.

Key Benefits of Using Posi-Joist:

- Design Flexibility: Thanks to metal connectors and wooden beams, Posi-Joist offers the ability to adapt to various architectural solutions and create longer floor spans.

- Longer Spans: Posi-Joist technology enables the construction of structures with longer spans, which is especially important for larger-scale projects.

- Easy Installation: The Posi-Joist system simplifies the integration of engineering systems, such as electrical installations and ventilation systems.

- Reduced Material Costs: The lighter construction means less material consumption and faster installation, reducing costs for both the manufacturer and the end consumer.

- Sustainability: Posi-Joist constructions promote efficient resource use and reduce waste.

Where Can Posi-Joist Be Used?

These solutions are ideal for private houses, apartment buildings, offices, and industrial projects. Additionally, combining Posi-Joist with SIP panels provides a complete construction package that ensures high efficiency and reliability.

We are proud to offer our clients such a modern and efficient technology that meets the highest industry standards. If you have any questions or would like to learn more about Posi-Joist solutions, please contact us!

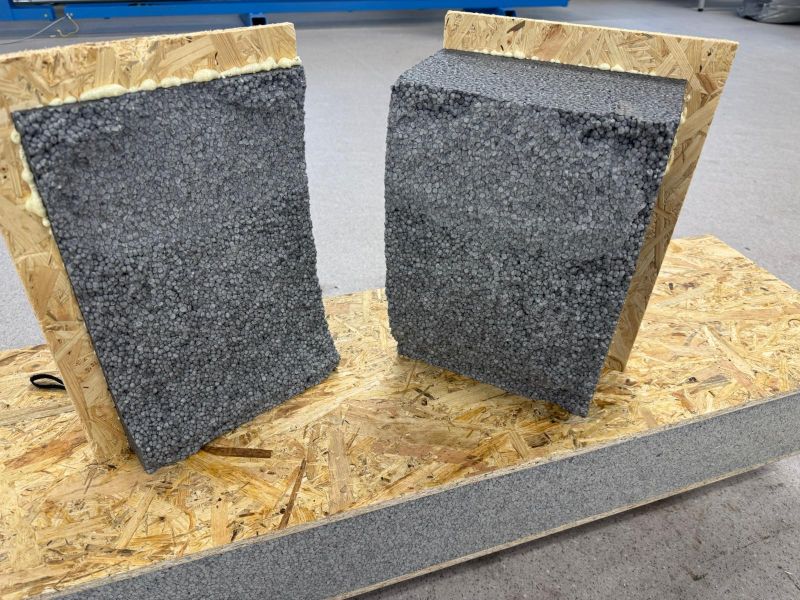

Testing the Durability and Quality of SIP Panels

Test 1: Strength and Tool Challenge

In the first experiment, a SIP panel piece measuring approximately 1 meter by 1 meter was used. The goal of the test was to assess the adhesive bond strength between the OSB boards and the NEOPOR core. Initially, attempts to separate the panel layers using only manual force demonstrated that the bond could withstand significant mechanical stress.

A heavy tool—a pipe wrench—was then used to separate the layers. After more than 20 strong impacts on the edge of the OSB board, the panel piece was broken. However, the results showed that the adhesive joint remained intact, while the fracture appeared within the NEOPOR material itself.

This result confirms the high manufacturing quality and durability of NEOPOR EPS-80. Even in a small format, the material withstood significant mechanical stress that traditional insulation materials, such as mineral wool, cannot endure.

Conclusion: The experiment demonstrated the high quality of the adhesive bond and the panel's overall durability.

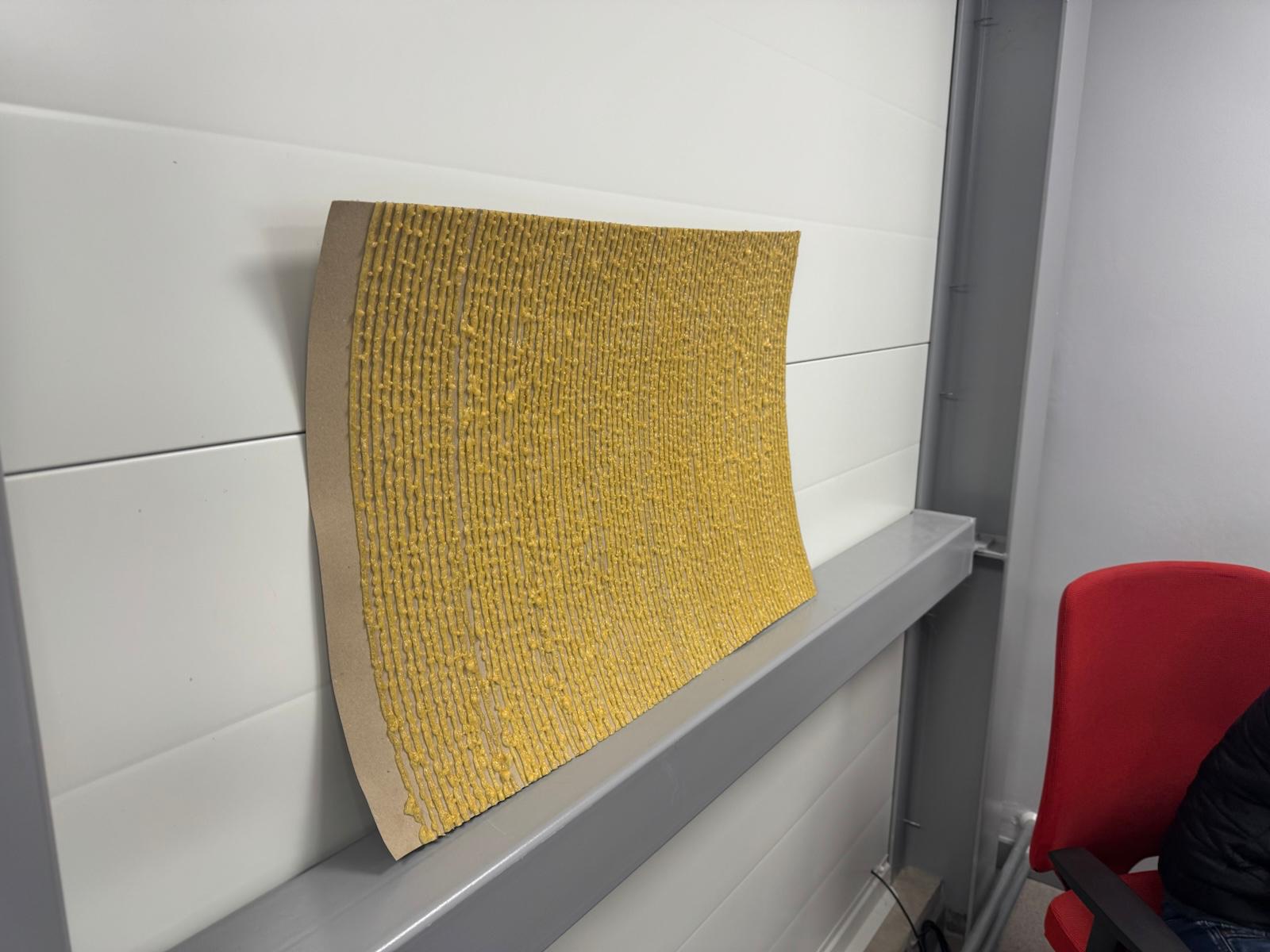

Example of adhesive application density:

Test 2: Long Panel Strength Test

In the second experiment, a longer piece of NEOPOR EPS-80, measuring 3 meters in length and 26 cm in width, was tested. The aim was to determine whether the board could be broken by applying pressure to its central part.

During the test, the board was placed on two wooden supports so that its middle section was unsupported. Initially, a 90 kg load, equivalent to a person's body weight, did not break the board. To further test its strength, two additional people were added, bringing the total load to 270 kg. Despite the significant pressure, the SIP panel remained intact and did not produce cracking sounds.

Conclusion: The test results showed that larger SIP panels provide even greater durability and can withstand significant loads.

Why SIP Panels Are Superior

The high strength of SIP panels lies in their monolithic structure. Unlike traditional timber frame constructions filled with insulation materials, SIP panels are an integrated system where OSB and NEOPOR form a cohesive unit. This structure ensures even load distribution and eliminates weak points typical of other materials.

For projects requiring long-lasting, energy-efficient, and durable solutions, SIP panels are an ideal choice. The conducted tests further confirmed the reliability and quality of these panels, making them an indispensable solution for various construction needs.

Foundations for SIP Panel Building

We often encounter the question – what foundation should be chosen for a SIP panel house? In this article, we will try to answer all your questions. We will review the 3 most popular foundation types suitable for SIP panel house construction.

The 3 most popular foundation types we will review are as follows:

- Slab foundations

- Pile foundations with an insulated floor panel

- Strip foundations

Slab Foundations

If you plan to build a year-round house starting from 100 square meters and there are no significant obstacles in the construction area, such as marshy soil or a thick layer of replaceable topsoil, it is recommended to choose slab foundations. We recommend the Tenapors L system, which is easy to install on-site and does not require additional formwork. Heating pipes for underfloor heating can already be embedded into the foundations, which means the heating system is built together with the foundation.

Pros:

- Solid construction

- Continuous thermal insulation of the foundation

- The possibility to install underfloor heating during foundation construction

Cons:

- Concrete works are heavy and require experience

- Communication systems must be planned in advance, such as sewage

- Time-consuming ground preparation

Pile Foundations with Insulated Floor Panel

This is the technically simplest flooring solution. It avoids concrete work during the entire process. The technology involves screwing in screw piles or driving in concrete piles. To determine the correct pile length, a soil geological study is required.

Unlimited possibilities with SIP panels

SIP panel construction has been well-known in the United States for a long time. The demand for more energy-efficient buildings and faster construction processes has made the use of SIP panels a logical dry construction method in Europe.

SIP panels can be used for the construction of extensions and holiday cabins, as well as for building large, energy-efficient single-family homes even in the coldest regions.

In the near future, we will be publishing several standard projects for both small buildings and complete residential homes. The biggest benefit of purchasing such standard products for the client will be the good price, proven solutions, DWG project files to provide to their architect for land allocation and building permit approval.

The walls shown in the pictures represent half of the house, which a team unfamiliar with SIP panels assembled in two days. This picture was taken on the evening of the first day. The house has an area of 105m² and a wall height of 3 meters.

Currently, the introductory price for this project is only €8500, including VAT, for the factory package.

More details here - "105m² House with 4 Bedroom Layout"